Dickson Industries Introduces New Flat-Bed Knitting Capabilities

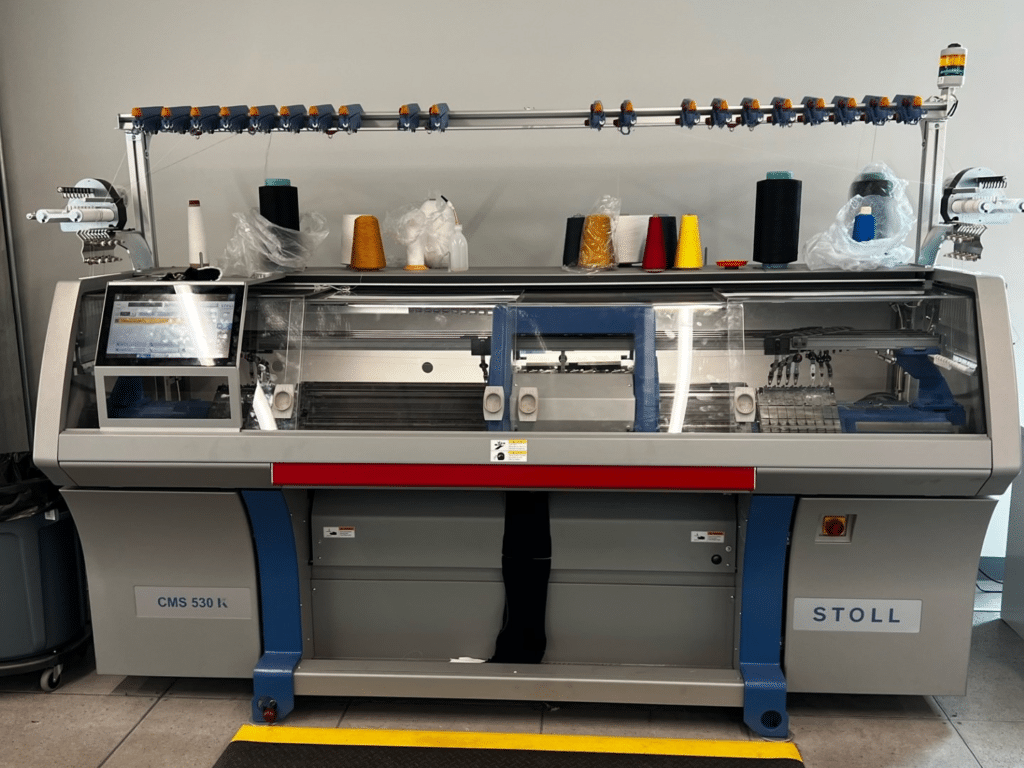

Dickson Industries, a leading manufacturer of knitted fabrics, is excited to announce the expansion of its knitting capabilities with the purchase of new Stoll flat-bed knitting machines. More efficient and detailed in design, these innovative machines reduce waste with remarkable precision, allowing Dickson to continue meeting the needs of its customers while creating a wide range of new offerings for the medical, furniture, fashion and automotive industries.

With flat-bed knitting, Dickson Industries has unlocked a new level of production capability. This cutting-edge technology ensures an even tension on the yarn, enabling the creation of whole garments with minimal or no cutting required. This process offers a multitude of benefits that drive efficiency, consistency, and design precision.

Benefits of Flat-Bed Knitting:

- Consistent results: Flat-bed knitting machines produce fabric with more consistent tension, which results in a higher quality product.

- Reduction of waste: Flat-bed knitting machines require less yarn than circular knitting machines, which reduces waste.

- Reduction of post-knitting labor: Flat-bed knitting machines can produce fabric that is ready to be shipped, which reduces the amount of labor required for post-knitting operations.

Made possible by an in-house programmer, Stoll machines are able to create custom technology and programs that satisfy our clients’ unique design requirements.

In the medical field, this new technology enables the production of compression socks and sleeves; in the fashion industry, Dickson manufactures beanies, sweaters, and more that combine style with superior quality. Entering the furniture market, Dickson is looking forward to providing ergonomic seating mesh for leading furniture brands across the country. And, actively exploring the field of geotextiles, our new flat-bed knitting technology is able to produce durable and high-quality textiles for various civil engineering applications, showcasing our dedication to delivering innovative solutions to meet the ever-evolving needs of our customers.

Bruce Goldman Joins Dickson Industries

Dickson Industries is also pleased to announce the addition of Bruce Goldman to its team. Bruce has over 40 years of experience in flat-bed knitting and is a versatile and technical textile knitting programmer. He has worked on a variety of projects, including fashion, medical devices, and vehicle parts.

Bruce will be overseeing production of Dickson’s new flat-bed knitting machines. He will work with the company’s engineers and designers to develop new products and to improve the efficiency of the knitting process.

A testament to the company’s continuous pursuit of excellence and innovation, this state-of-the art technology—employed by Dickson’s industry experts—will enhance efficiency while reducing waste and unlocking new possibilities for garment manufacturing. With a wide-reaching range of applications and a team dedicated to excellent service, this latest advancement pushes Dickson forward as a leading provider of innovative industrial solutions in the textile industry.

Contact Us to Learn More about Flat-Bed Knitting Services